Finally got the new crystal seated! 2 inches forward, . . . you know the rest.

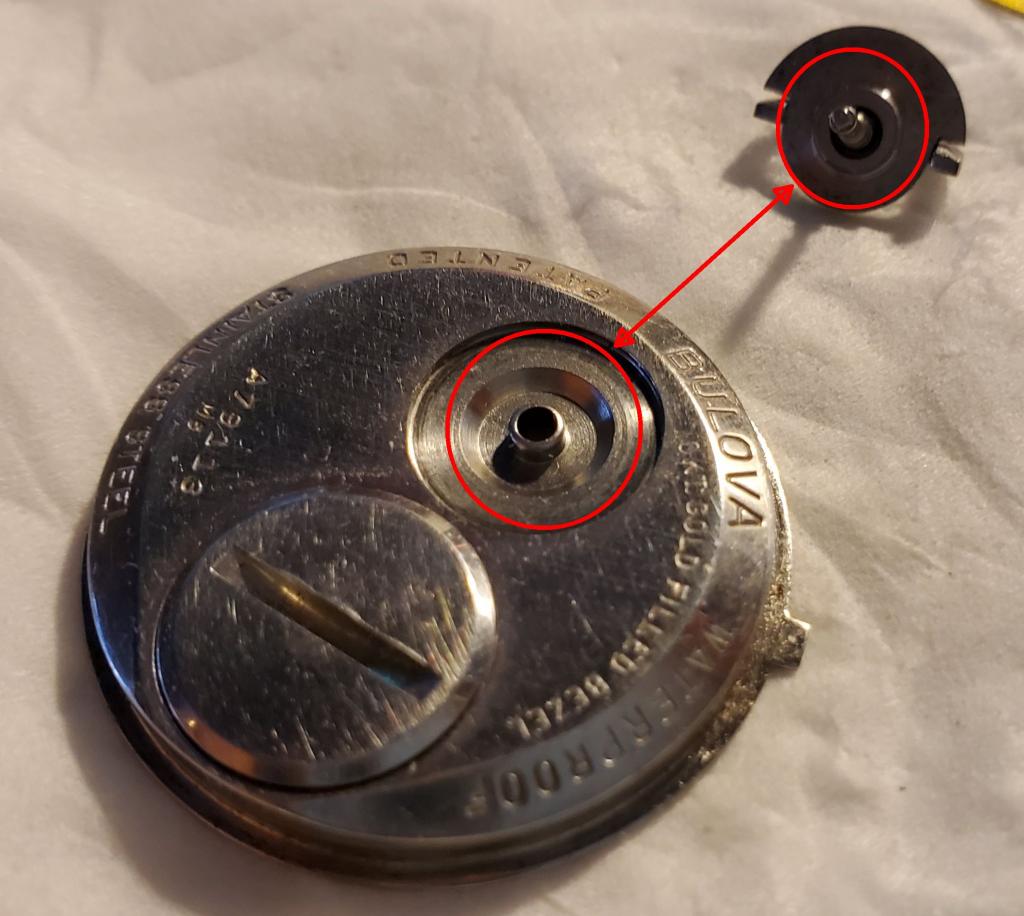

After assembly, the flyback stem on the back won't adjust the hands. Looking further, the stem has pushed the engagement gear out-of-mesh. Removing the stem allows the adjustment gear to engage its mate. So - something dimensionally changed. Using same case, (improper) dial support ring, movement, new rear gasket (thickness verified) and backing. (Have ordered the chapter/dial ring from 'nostalgia'/ebay.)

This assembly used to adjust and work before the crystal was replaced. I can't see any reason how the new crystal would affect the assembly stack up, to where the crown stem now appears too long. Is there a gasket that should go between the crown and the backing? Would the stem somehow lengthened coming out of the fly-back crown? (The movement does work though.)

In reply to Finally got the new crystal… by Mark W.

As you are installing the rear cover you should have the settings handle "lifted" and you should turn it as you are bringing the bezel and rear cover together to make sure the settings stem engages the engagement gear otherwise it will push the gear out of position and bend the engagement gear return spring...

I hope that makes sense?

In reply to As you are installing the… by Astronaut M2

In reply to Also, did you get the… by Astronaut M2

In reply to Sorry, I see that you did… by Astronaut M2

In reply to Sorry, I see that you did… by Astronaut M2

Don't use that incorrect dial ring spacer from a 218 because even if it has the correct thickness it still won't work right because the ID is too small and it will hold the movement from going in all the way as it should, You'll know if the movement is in right if you look where the rear cover gasket goes and the bezel lip and movement lip are both at the same height as each other...

In reply to Don't use that incorrect… by Astronaut M2

Thanks for all those tips, Astronaut.

Yes, the MR401 is on order.

When the incorrect dial space is in the stack up, the movement's edge and case bezel are co-planar with each other, oddly. It will be interesting to compare the 401 to the spacer I have now.

I have been careful to insert the crown stem to allow its square tip to smoothly engage its female engagement gear broaching - and it still (now) pushes that gear and leaf spring out of mesh. Does anyone know what the height of the stem should be as it protrudes from the flyback face? (For background, my career experience is a mechanical engineer packaging electronic components in smaller packages for telecom and military applications).

In reply to Thanks for all those tips,… by Mark W.

In reply to There are many dif length… by Astronaut M2

Astronaut,

As you suggested, the MR401 spacer ring is installed in the case (shoulder side to crystal), then the movement, gasket and back. The back retaining ring has been lightly torqued. I've also installed the flyback crown and stem, making sure the stem's male square and the movement's female square-in-gear are synchronized to mesh.

After assembly, the adjustment gear is out of mesh with the gear train (against the cantilever spring), however when the flyback level is flipped for time adjustment, the gear drops into mesh. Does that sound normal - for the gear to be pushed out of mesh when the flyback level is flat?

Thanks,

Mark