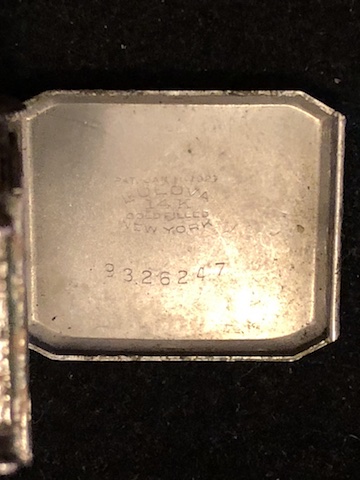

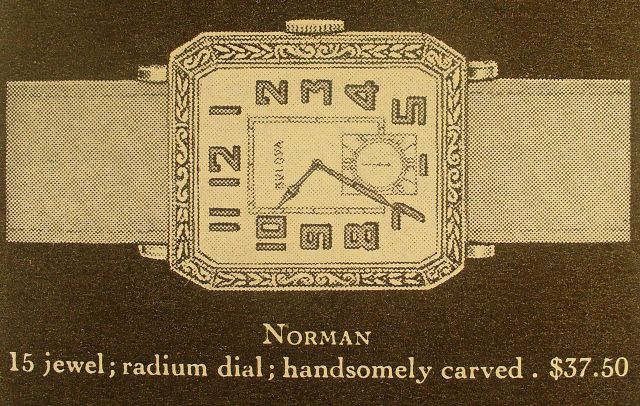

This appears to be 1929 Norman. It is a 14kt white gold filled and in dire need of an overhaul. It has a 9AT movement with a shield date code. Note the bezel is engraved and matches the ad.

I disassembled the watch and found some rusted screws. I did have a 9AT spare movement but it had a kinked hairspring. I was able to swap out the main plate and reassemble the watch. I am trying to get the balance moving but having issues due to it being out of balance and kinked. Probably going to have to get a new hairspring. These are especially fragile. Need to get the crystal too but it is looking better.

In watchmaking school, we spent 180 hours or whatever it was, straightening hairsprings.

To do it properly, you remove it from the staff, and place it on a piece of glass. If the distortion is mild, you can do it in situ, but this is one of those things where you really need to know what you're doing. The hairspring must be perfectly flat, perfectly concentric, and the terminal coil just so, as well as the overcoil if present. Sometimes the pinning point at the collet or stud gets twisted also. Adjusting a hairspring will invariably create a beat error, which is not easily remedied in these old watches. The balance complete must be removed from the balance bridge, and the collet adjusted with a special tool to align the impulse pin exactly in the centre of the travel of the tail of the pallet fork, exactly in the middle of the banking. It's a bit trial and error. This process is infinitely easier if there is a movable stud carrier.

It still makes me cringe when I see that I have to do it. Ideally, you just replace it, (hairspring) or even the balance complete.

In reply to In watchmaking school, we by Reverend Rob

Thank you. I can say without question the hairspraing has been the death of me. I have runied about a third of the ones I worked on. The other third run with a beat error like you mention an I get luck on the final third. I contine to get better at it but it is definitely a task that required hours of practice, keen eyes and the right tools. Thanks again.

There are actually hairspring manipulation videos on YouTube, I am really surprised by this.

Past a certain type of bend, the hairspring is compromised and cannot be repaired to operate within parameters. They will break, so actual kinks mean it is a lost cause. The modulus of elasticity of the spring changes over many years, and the springs get 'rubbery' for lack of a better word. When you think the slow ones used to do 432,000 alternances per day times however many years the watch has run, you can see why.

A modern watch running at 4 Hz makes 691,200 alternances per day.

One thing I should mention is that older watches especially will suffer from magnetic fields. The hairspring will become magnetised, as will various steel parts in the movement. Before any measurement or adjustment is ever done on a movt, it is always demagnetised first. In today's world there are many sources of this, not the least being cell phones.

Keep cell phones well away from vintage watches. I wrote a blog about this: